Company Overview: Valiant Packaging’s Meteoric Rise

Within the growing spirit packaging industry, Valiant Packaging has emerged as the leading manufacturer of customized glass bottles for wholesale. The company is based within Shandong, China, Valiant Packaging is a part of the Valiant Group umbrella and leverages over 20 years of experience in the field of glass production. Valiant Packaging has designed an integrated vertical model which includes mold making, glass production finishing packaging, and decoration. This gives them the complete control over the cost, quality as well as lead time.

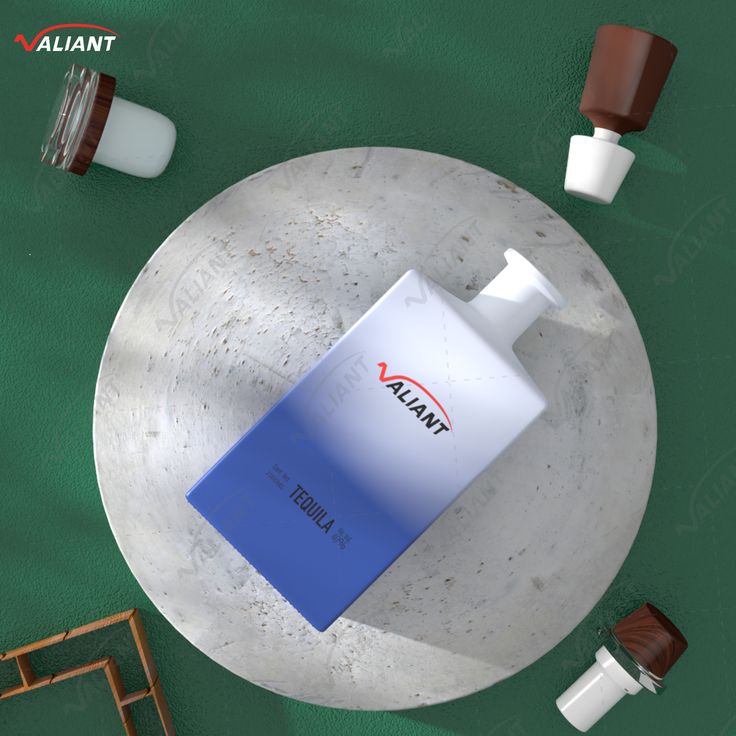

As the Dean Fan, the CEO Dean Fan, Valiant Packaging places a high value on accuracy, innovation and sustainable development. From its cutting-edge mold facility to its sophisticated decoration capabilities The company is proud in its ability to provide custom glass products that are tailored to the distinctive branding needs of customers in the wine, spirits beer, and specialty beverages sectors. If the project involves the traditional 750mL whiskey decanter, or a contemporary and sculptural gin bottle every project starts by having a consultation with the client. In this stage the design team of Valiant works closely with stakeholders from the brand to translate concepts from abstract into 3D-specific renderings showing color, shape embossing, shape, and other surface treatments choices. Through this process, Valiant ensures every bottle meets essential requirements such as durability and compatibility with liquids, but also functions as an ambassador for the brand in the crowded shelves of retail.

Market Trends: Rising Demand for Wholesale Custom Glass Bottles

The market worldwide for customized glass packaging specifically in the spirit industry is experiencing rapid growth in the past few times. There are a variety of converging reasons that drive this growth

- Premiumization and brand differentiation With consumers becoming more aware of their preferences, companies realize the packaging as an indication of the products’ perceived value. A custom glass bottle with distinctive contours and embossing or color-coordinated glass–shows the highest level of craftsmanship, and is a the higher prices. The majority of retailers assign a high-end shelf for spirits that have standout packaging. This creates an positive feedback loop between investment in design and sales.

- Sustainability mandates

The pressures of regulation and the increasing preference of consumers for recycled materials. Contrary to other materials, glass is infinitely recyclable without losing its purity or its quality. Companies that want to show green practices choose to use glass bottles, frequently highlighting the post-consumer recycling percentage contents. The trend is driving the demand for wholesale glass bottles with eco-friendly certifications along with a modern aesthetics. - Craft Distillery Growth

All over the world micro-distilleries as well as craft spirit businesses have grown exponentially. Smaller producers often seek limited edition batches (as as low as five thousand units) with distinctive bottle designs for establishing niche brands. Valiant Packaging’s structure is created to handle large-scale orders as well as shorter production runs. It is the ideal choice for small and craft-based producers as well as multi-national conglomerates. - Technology-driven advancements in decoration

Technologies like UV-curable paints, digital direct-print labels, as well as multi-layer glass tinting, allow manufacturers to produce complex high-quality graphics directly onto the bottle. These techniques for decoration reduce dependence on labels made of paper, which reduces waste. They also improve design flexibility, increasing the appeal of personalized glass bottle designs..

According to industry analysts, between 2024 and 2029 the glass packaging market for spirits is projected to expand with a compound annual rate (CAGR) about 6percent. As demand is growing across North America, Europe, Asia-Pacific as well as the emerging markets like Latin America and Africa, Valiant Packaging’s extensive capabilities enable it to gain a significant market shares.

Precision Craftsmanship: From Concept to Creation

The heart of Valiant Packaging’s proposition is high-quality manufacturing. Every custom bottle is developed through various meticulously monitored steps:

- Conceptual as well as Designer Consultation

This process starts with a thorough discussion. The designers at Valiant gather data on the brand’s identity, demographics of target as well as the impact they want to have on shelves. They create moodboards, 3D CAD renders and samples of materials that are in line with the vision of the client. Initial prototypes, which are often 3D-printed to scale, permit the brand team to physically manipulate suggested shapes and test aesthetics and ergonomics prior to molds made of steel. - Technical Engineering and Feasibility Analysis

When an approved design is in place the engineering department at Valiant conducts structural analysis and including the thickness of glass walls as well as weight distribution as well as capacity demands. When it comes to spirits that have long-term process of aging or with higher proof levels, the durability is essential. Our team uses the finite element method (FEA) to study the effects of thermal stress, pressure and drop resistance. The analysis guarantees that the finalized design will be able to withstand variations in manufacturing, transport stress, as well as handling by the end-user. - Mold Manufacturing and Iterative Testing

Valiant’s manufacturing facility in-house uses high-grade alloy steels, as well as precise CNC machine tools to design molds with tolerances of +-0.05 millimeters. Features like embossed logos, or elaborate relief pattern designs are added by micro-engraving the surface of the mold cavity. Following initial mold creation tests, trials are produced to create containers that are subject to physical, optical, as well as structural test. All adjustments that are required, like fine-tuning the draft angle to facilitate mold release or tweaking embossing thickness–are made prior to when the production process is fully-scaled. - Custom Glass Formulation

The basic materials–silica sand, soda-ash, limestone and certain mineral oxides are mixed and measured using proprietary formulas. Through adjusting the concentrations of mineral oxides, Valiant achieves a wide range of colors, from clear glass flint to amber, cobalt blue, emerald green as well as gradient shades. Glass compositions that are specially designed for use in applications that need the highest chemicals resistance (e.g. bottles of liquors or spirits with citrus infusion) to stop the leaching of flavor and alteration. - Automated Quality Control and Production

Valiant utilizes individual Section (IS) equipment for bottles with standard shapes. They also have semi-automated blow and blow lines for more complicated design. Each IS machine focuses on repeatability and throughput–producing thousands of uniform bottles per day. Sensors that monitor real-time parameters, like glass viscosity temperature and pressure of air. If any parameter is found to be outside of the thresholds set, alarms trigger the furnace’s operators to change their adjustments immediately. This will keep the defect rate below industry norms of 5 percent. - Surface Decoration and finishing

In order to create distinct brand recognition, Valiant offers a suite of high-quality solutions:- Silk Screen Printing Perfect for solid, saturated color blocks and logos with large sizes. Curing can be done using UVovens based on thermal to guarantee long-lasting adhesion.

- Spray Coating provides a range of finishes from glossy to matte. UV-curable coatings can be found to speed up cure time and better scratch resistance.

- Acid Etching and Sandblasting produces a frosty appearance that is perfect for subtle branding and patterns that reflect light in different ways.

- Hot-Foil stamping Apply metallic accents like gold, silver, or copper directly onto the glass’s surface, giving a premium, luxurious appearance.

- digital Inkjet Labeling Allows printing with variable data–batch numbers barcodes, QR codes or other numbers without the need for a separate label application.

- PVC Shrouds and Pressure Sensitive Labels offer flexibility to regions that are frequently targeted by promotional efforts that allow labels to be easily swapped without damaging the glass’s strength.

- Quality Assurance and Final Inspection

Prior to shipping the product, every batch goes through an inspection that is multi-tiered:- Dimensional verification Random samples are tested using digital calipers that verify the wall thickness, height as well as diameter tolerances.

- Optical Clarity: The bottles are positioned against glowing LED panels that show any striations, micro-bubbles or inclusion imperfections.

- The Weight Consistency Weight of bottles is measured using precision scales in order to make sure that the variance is within +1 grams of the desired weight.

- decorative durability Scratch and abrasion tests are conducted on the decorative surface to confirm their resistance during handling and transportation.

Global Reach: Strategic Partnerships Across Five Continents

In order to serve a global clients effectively, Valiant Packaging has established an extensive global network including regional headquarters, warehouse hubs logistics alliances.

- North America

Valiant has an office for distribution located in Los Angeles, California, where they keep safety stock of SKUs that are popular, like 775 mL bottles of whiskey flint and 700 mL of emerald green Gin bottles. The buffer stock facility guarantees the U.S. clients receive orders within 7 business days of inventory items. When it comes to custom-designed projects, the lead time for all phases of production, manufacturing, mold fabrication, packaging, and decoration–is usually between 8 and 10 weeks. - Europe

A satellite office located in Amsterdam is Valiant’s European headquarters. The clients who use this office in France, Germany, Italy as well as in the United Kingdom receive localized support to ensure compliance with regulatory requirements (e.g., EU Directive 94/62/EC concerning packaging waste) as well as design-specific language consultations. The year 2024 saw Valiant launched a regional store located in Rotterdam that will reduce inland transport time by 30 percent and providing full Customs clearance support. - Asia Pacific

Outside of its main manufacturing facilities located in Shandong, Valiant operates a showroom located in Guangzhou for 3D printed prototypes as well as interactive VR model simulations. The immersive experience allows Asian customers to “virtually” engage with bottle mock-ups, and examine the contours and details at a large scale prior to committing to molds made of steel. By 2023 Valiant has expanded the capacity of its warehouses in Singapore in order to speed up deliveries to new markets like Vietnam, Thailand, and Indonesia. - Australia and New Zealand

Working with distributors local to Sydney as well as Auckland, Valiant has responded to the region’s vibrant craft gin and premium beers scene with specific UV-resistant coatings, as well as lightweight bottles. For 2024, the number of the number of bottles shipped to Australia rose by 62%. Gin producers noting Valiant’s speedy turnaround time and custom colors, such as the famous cobalt blue bottle that is used to make a popular Australian Gin–as the most distinctive features. - Latin America & Africa

In recognition of the rising demands for premium spirits across Mexico, Brazil, and South Africa, Valiant has established partnerships with importers to have local inventory buffers. An important collaboration with Baldore, a producer of Mexican spirits that spans multiple categories in the summer of 2018. Their projects in collaboration were focused on the delivery of glass bottles that contain at the least 50% post-consumer waste which emphasized the environmental commitments of both brands. For South Africa, Valiant teamed with local eco-initiatives in order to test a buy-back of bottles program, which allows customers to exchange empty bottles to receive incentive to recycle.

Utilizing the most efficient port routing methods by utilizing multiple modes of transport (sea rail, sea, and trucks) as well as maintaining communications using a custom website for tracking, Valiant ensures that clients stay informed on every step–mold finalization, production beginning and quality approval, as well as shipping containers to customs, clearing as well as the final delivery.

Sustainability & Environmental Stewardship

Today, when environmentally conscious customers and stricter regulations dictate decision-making in packaging Valiant Packaging’s commitment to sustainable practices has been a central part of its branding image.

- Recycling Glass Integration

More than 40 percent of the glass that Valiant uses as feedstock is derived from post-consumer Cullet. Incorporating recycled glass, also known as cullet Valiant reduces materials used, saves energy (up up to 30% lower energy consumption per melt cycle) in addition to reducing environmental burdens. Customers often use this information in their environmental marketing. They highlight the average reduction in carbon footprint between 15 and 20% per bottle, compared to original glass bottles. - Efficiency-based furnace operation

The traditional glass furnaces are major consumption of energy. Valiant’s furnaces use regenerative and regenerative burners which make use of waste heat to warm the combustion air that is coming in. This technique reduces the use of natural gas by about 15 to 15%. In addition, the heat from exhaust is reused to ensure the same operating temperature throughout winter, decreasing the need on heating sources from outside. The year 2024 was the first time Valiant has reported 12 percentage decrease in its total carbon dioxide (GHG) emissions as compared to its baseline for 2020. - Renewable Energy Use

Valiant have constructed the on-site photovoltaic (PV) arrays which provide about 8% of its energy requirements daily for its packaging and decoration services. The plan is in the works to increase solar power to provide 20% of usage of energy in the facility. The recent Power Purchase Agreement (PPA) in conjunction with the local wind farm is expected to further incorporate renewable energy into the production grid. The goal is to achieve 25% renewable energy use goal in 2027. - Water Conservation & Closed-Loop System

Glas production needs large quantities of water, both for cooling as well as cleaning. Valiant installed a closed-loop system to recirculate cooling water and reduces the withdrawal of freshwater by 60 percent. The wastewater is treated on site using the filtration tanks and sedimentation tanks. These are used to get rid of silica and heavy metals prior to safe disposal, assuring that the local environment regulations are met as well as reducing the ecological footprint. - Eco-friendly Secondary Packaging

beyond the production of glass, Valiant offers sustainable secondary packaging alternatives, including corrugated cardboard boxes composed of 100% recycled paper biodegradable foam inserts and recyclable shrink wrap. Logistics experts optimize pallets for maximum capacity of containers, while reducing the quantity of deliveries and the carbon emission.

The effectiveness of these efforts is confirmed by the third-party audits and certificates–ISO 14001 (Environmental Management) as well as ISO 45001 (Occupational Health & Safety). Recognition from the industry include that of the 2022 Glass Industry Sustainability Award as well as The 2024 Packaging Innovation honor for a line of gradient-tinted bottles that reduces temperature retention in transport.

Signature Success Stories

To demonstrate the impact of Valiant Packaging take a look at the following case studies, which illustrate the combination of the latest technology, customization and sustainable development:

1. Regal Reserve Whiskey: From Concept to Icon

Regal Reserve, a premium whiskey brand that was launched in Colorado in 2023 required bottles that exuded history and exclusiveness. In collaboration with Valiant’s design team, Regal Reserve opted for the heavy-weighted glass bottle that features an embossed mountain design and an oak-wood veneer that was hand-applied on the shoulder. Valiant’s engineers created the mold to replicate the delicate embossing process, which ensures consistency in clarity and depth over hundreds of thousands of units. The resultant bottle was sold at the price of 20% more as well as Regal Reserve experienced a 35 percent increase in sales in the first three months following the launch. Much of the success due to the bottle’s appealing tactile feel.

2. TerraVin Organic Wines: Embodying Sustainability

TerraVin, a New Zealand-based organic wine cooperative that aimed to express its green values through packaging. Valiant offered a light flant-glass bottle that contained 60% post-consumer cullet. It added a matte finish that gave it an artistic, “hand-crafted” feel. In reducing the real estate of labels and permitting the wine’s natural color to show across the bottle, TerraVin presented authenticity. Research revealed the fact that 70% of customers attributed the label to more environmental responsibility. At the end of 2024, TerraVin’s new packaging design resulted in a market share of 12 percent increase in certain New Zealand and Australian regions.

3. Ocean’s Edge Gin: Influencing Coastal Markets

Ocean’s Edge Gin, an Australian inspired spirit with a coastal flavor, needed packaging that was reminiscent of the sea breeze and tropical breeze. Valiant’s design team developed an aqua-blue colored glass bottle that resembles an ocean wave. The embossed seaweed designs on the underside made for a tactile experience, while the UV-resistant coating was specially designed to maintain the color’s integrity in sunlight. The silver highlights of the hot-foil bottle’s label captured the glimmer of light from the ocean. The launch of 2024 saw Ocean’s Edge Gin saw a 40% increase in distribution throughout Florida as well as Caribbean resorts. The bartenders as well as retailers applauding its visibility as well as its weatherproof characteristics.

4. Bianco Spirits Co.: A Triangular Challenge

Bianco Spirits Co., an exclusive Italian distillery, was looking for the triangular bottle that would be distinctive during the Paris Spirits Expo 2024. Valiant’s mold makers carefully balanced the bottle’s three faces flat by using structural ribs in order to ensure an even wall thickness, and to prevent tension concentration. The product received the “Best Packaging Design” award at the show, but it was also able to secure long-term sales agreements in France, Germany, and the United Kingdom.

These success stories underscore Valiant Packaging’s ability to translate abstract brand concepts into tangible, market-winning glass solutions–regardless of geographic location or production scale.

Customization Edge: Tailoring Solutions for Every Brand

Valiant Packaging’s distinctive feature is the ability to provide customized solutions. Instead of forcing clients to fit into existing SKU catalogues Valiant is a close partner to create unique packaging designs. Some of the most significant aspects of customizing include:

- Shape and profile variations

Utilizing a collection of hundreds of base geometries ranging from minimalist, sleek cylindrical cylinders, to intricate, sculptural decanters, Valiant’s R&D team is able to create new forms. With the help of advanced 3D CAD technology and 3D printing (3D printing) to create prototypes, customers are able to physically test ergonomics of designs the stacking capability, as well as the footprint of shelves prior to mold manufacturing. - Glass Spectrum Color Spectrum

In addition to traditional flant (clear) and amber or forest greens, Valiant has tinted shades like cobalt blue the smoky gray color, burgundy and custom gradients. Color creation occurs in the stage of furnace by adding precise mineral oxides, such as chromium for deep greens, cobalt to create vibrant blues as well as sulfur or selenium compounds for the amber-gold hues. The limited edition seasonal palettes, like pastel ombres that are used in spring liqueurs –are possible with a few production changes. - Debossing and Embossing

Embossed components–brand logos, serial number, or intricate patterns are incorporated straight into the cavity of mold. Embossed depths range from 0.5 to 2.5 millimeters, while also preserving the the mold’s lifespan. Debossed texture (recessed zones) can add additional attraction and help with design placement, especially if a partially-label layout is preferential. - Specialty Finishes & Textures

for brands that want to stand out tactilely as well as visually. Valiant uses a variety of coatings: matte spray coatings satin-smooth lacquers and areas of sandblasting that are granular, as well as metallic-infused varnishes. Every finish is not just arouses certain sensory sensations but may be used for other purposes as well such as frosted areas concealing tiny glass imperfections, while matte neck finishes enhance the grip when handling. - Integrated Closures & Accessories

Valiant collaborates with the most reputable closure makers to provide additional components- Waxe-dipped corks Perfect for top-of-the-line wine and spirits that have a timeless design.

- Screw Caps made of stainless-steel provide a contemporary secure, waterproof seal.

- Custom Wooden Toppers made from sustainably harvested wood, such as walnut or oak. They are usually printed by laser engraving.

- The leather Sleeves or Metal Medallions Add them to the neck of the bottle, making a luxurious unboxing experience.

- Labeling and Direct Print Alternatives

Valiant’s direct-printing inkjet digital technology can produce photorealistic pictures with barcodes that are high-resolution and QR codes–that are applied directly to the glass’s surfaces. The process removes the need for label paper, which reduces loss and minimising imperfections. Customers who want labelling that is removable and pressure sensitive, Valiant supplies bottles pre-treated using a specific primer, which ensures perfect adhesion, and effortless removal when needed. - Limited Editions and seasonal collections

Flexible production lines permit swift tooling adjustments and small batch runs, sometimes at as little as five thousand units. This flexibility lets brands assess market reactions with limited-edition release: e.g.”Autumn” is a themed whiskey collection featuring amber-tinted glasses and copper foil leaf designs. Valiant’s capabilities for rapid prototyping using 3D-printed molds cut development time from a long time to one or two weeks.

By offering such end-to-end customization, Valiant Packaging transcends the traditional roles of a contract manufacturer, evolving into a strategic partner that guides brands through design, regulatory compliance, manufacturing, and distribution–ensuring that every bottle delivered amplifies the client’s unique story.

Logistics & Supply Chain: Ensuring Timely Delivery

Delivery of glass bottles that are fragile in time requires careful control of the supply chain. Valiant Packaging has developed a multi-faceted logistics approach that is designed to reduce transit time as well as reduce the cost of freight as well as ensure the quality of product:

- Inventory Buffering and Security stock

for staple SKUs, such as clear 750mL wine bottles or 700mL whiskey decanters – Valiant keeps safety stocks at regional storage facilities (Los Angeles, Amsterdam, Guangzhou). Buffering can reduce delay times on repeated orders and allows customers to replenish their inventory in 5-7 working days when they have in-stock items. - Regional Warehousing

Strategic Warehouse hubs within Los Angeles (USA), Rotterdam (NL) and Singapore (SG) offer the proximity of important ports and distribution centres. The facilities house certified samples, molds as well as finished products, giving customers a faster process to get their product into North America, Europe, as well as Asia-Pacific. Consolidation solutions combine multiple-variant orders–e.g. bottles of different designs or colors into a single shipment in order to maximize the use of containers. - freight forwarding partnerships

Conscient of the fragility of glass, Valiant collaborates with specialized freight forwarders with experience handling broken items. The bottles are packed with shock-absorbing cushions, reinforced by edges protectors and then covered with a humidity-resistant plastic to stop moisture from entering when shipping ocean-bound. Air freight is an option for orders that require immediate attention. Smaller volumes of bottles are delivered within 10-12 days after shipping of Shandong up to Los Angeles. - Real-time Order Tracking and Transparency

Customers have access to a private web-based portal which tracks every order’s progress from production of molds to the final delivery. Automated notifications alert stakeholders about important milestones like manufacturing begin, quality inspection signature-off and the loading of containers, customs clearance and expected time of arrival. This information allows companies to coordinate the launch of promotions and launches in a secure manner. - Customs Compliance & Documentation

Valiant’s dedicated compliance team handles all export documentation–commercial invoices, packing lists, certificates of origin, and, where applicable, phytosanitary certificates for wooden closures. Pre-writing the necessary documents that are in line with the the regulations for imports of countries that are applicable to them (e.g., FDA requirements for the USA, EU-CE markings for Europe). USA and EU-CE markings for Europe), Valiant minimizes the risk of delays in customs. - Sustainable Transport

In addition to glass production Valiant is determined to lower the carbon footprint of its logistics by optimizing their efficiency:- container load optimization A 3D-packaging software designs container loading in order in order to improve the density of pallets and thus reduce the overall quantity of the shipments.

- Rail and Multimodal Routes If possible, products move by trains between Shandong into European distribution centers, cutting carbon dioxide emissions by as much as 40% as compared to sea routes.

- Carbon neutral Shipping Options To those with a strict ESG objectives, Valiant offers carbon offset programs which invest in certified carbon reduction initiatives, for example, reforestation and renewable energy installation.

This combination ensures time-bound delivery, reduce shipping costs per unit and increase the confidence of customers in Valiant Packaging’s capability to satisfy any logistics demands.

Leadership & Dream Team

Valiant Packaging’s successes are the result of an enthralling and innovative management team that is backed by talented technicians, skilled craftsmen as well as logistics experts that work together to bring every custom idea to fruition.

- Dean Fan, Chief Executive Chief Executive

with a background in academics and industrial engineering, and more than twenty years of experience working in glass fabrication, Dean Fan drives Valiant’s strategy. Under his leadership Valiant has increased its international footprint, made investments massively in environmental initiatives and formed partnerships with top spirits companies. His core principle–“Every bottle must convey an story”–permeates all departments, and ensures that the design, engineering and production teams stay focused in delivering the brand’s story in glass. - Dr. Mei Chen, Vice President of Research & Development Holding a Ph.D. in Materials Science, Dr. Chen leads Valiant’s R&D division, which is where the latest innovations in the manufacturing process and glass formulation is a regular occurrence. Her team led an Ultra-Thin Glass (UTH) initiative, cutting the weight of bottles by as much as 15%, without jeopardizing the structural quality. Dr. Chen’s current projects involve the development of bio-based glass additives that are derived from agricultural waste as well as exploring special coatings that can will extend the shelf life of spirits that are acid-forward.

- Leo Wang Director, Global Sales & Marketing

With more than 15 years’ experience in the international market, Leo orchestrates Valiant’s market expansion across North America, Europe, as well as emerging regions. The company works closely with its clients to offer data-driven insight regarding cost-benefit analysis for various kinds of glass, finishes and logistical choices. The expertise he has gained in the negotiation of freight and shipping through rail routes has helped in the reduction of lead times as well as the cost of freight for customers. - Sophie Ramirez, Creative Director

A graduated from the Rhode Island School of Design (RISD), Sophie leads the creative studio that handles the development of concepts mood boards, mood boards and 3D renderings. Sophie works directly with brands’ marketing departments to make sure that elements of design, such like color gradients, embossing patterns and labels-free workflows are in sync with overall messages for the brand and consumer impressions. - Chen Li, Sustainability & Compliance Manager

In charge of overseeing the initiatives to protect the environment, Chen Li ensures that Valiant’s processes are compliant with the global standards (ISO 14001 and ISO 45001) and over. Chen Li oversees the development of alliances with energy suppliers for a greater use of renewable energy as well as coordinates third party environmental audits as well as oversees the closed loop water recirculation systems which save 60 percent of water consumption on site. - Tech & Shop-Floor Team

from mold-makers, machinists and even automated line technicians as well as quality assurance specialists Shop floor personnel at Valiant provide each day with a high level of high-quality service. Modern programming skills, such as the ability to detect defects in real-time on IS machines – paired with skilled glass-blowing abilities ensure that Valiant ensures high efficiency and low defects. Regular training and cross-functional sessions promote sharing of information as well as process improvement.

The combination of leadership with vision as well as a dedicated technical team results in a constant culture of advancement. Through coordinating KPIs across departments, such as a defect rate target below 1 percent, energy usage cuts of 5 percent yearly as well as on-time delivery rate over 98%–Valiant Packaging always exceeds clients’ expectations.

Conclusion: Leading the Charge in Wholesale Custom Glass Bottles

With the demands of consumers and changing the regulatory landscape evolves Glass packaging maintains its position as the product that is preferred for top spirits, wine and a variety of specialty beverages. Valiant Packaging has positioned itself as a leader in this shift because it combines high-end manufacturing, comprehensive customization with unwavering sustainable practices. Valiant’s vertically integrated manufacturing facilities – from mold production to final decoration, coupled with its global distribution system make sure that startups as well as multinational corporations can count on Valiant to deliver on time, top-quality environmentally-friendly wholesale glass bottle.

With energy-efficient furnaces, closed loop water systems and other green energy projects, Valiant not only meets and often surpasses standards for environmental sustainability. Valiant’s innovative approach to research and development — including Ultra-Thin Glass, bio-based ingredients as well as NFC-enabled smart bottles – signals an era where packaging can do more than simply hold spirits. It tells stories and engages customers digitally and reduces the environmental footprint.

Through ensuring transparent communication through the real-time tracking of orders, creating alliances with logistics companies and maintaining a top-performing staff that are committed to innovation Valiant Packaging transforms each client’s concept into a reality that is ready for market. When it comes to creating a limited-edition batch of 5,000 bottles or constructing millions of identical units to distribute globally, Valiant merges artistry with the rigor of engineering to create unforgettable, distinctive packaging solutions.

If you are a wine, spirits or other brand of specialty beverages that wants to enhance its brand or differentiate itself by a distinctive designs, and highlight its environmental commitment, Valiant Packaging stands as the only choice. It has a track record of success with industry accolades in sustainability and innovative design and a vision for the future, Valiant is not just making bottles but creating the future of packaging for beverages all over the world.