The phrase GPI 33/400 could seem confusing initially, however it’s a widely-accepted and vital standard for the field of glass packaging. for businesses operating in the alcohol, pharmaceuticals cosmetics, and oil-related industries Understanding this requirement could mean the difference in successful packaging or failing.

So, what does GPI 33/400? The term “GPI” stands for Glass Packaging Institute, which is the body that defines bottle finishes throughout the entire industry. The value “33” refers to the the outer size of the neck in millimeters. The”400″ is the measurement of the outer diameter. “400” refers to the kind of thread, specifically the one-way thread type that allows closures to be turned to be securely removed as well as repeatedly.

The standardization process has evolved into an industry standard, which allows the possibility of cross-compatibility and efficient production as well as reliable performances. It doesn’t matter if you’re a distillery brewing high-end gin or a cosmetics manufacturer making natural serums in bottles, choosing bottles that have the GPI 33/400 finish guarantees consistency in outcomes.

Why Standardization Matters in Packaging

In an increasingly globalized manufacturing and supply chain, standardized packaging components such as that of GPI 33/400 finishing of bottles are crucial. If there were no common standards, producers could face significant challenges trying to connect bottles and closures, make bottling lines automated and even expand into global market.

We’ll look at the reasons why these requirements are crucial:

- Cross-compatibility If you purchase closures from Europe or in the U.S., a GPI 33/400 finish indicates that they’ll work.

- Errors are reduced Incorrect closures may cause losses, leaks or even contamination.

- Rapider development of products There is no need to reinvent the wheel with every item.

- Lower costs for production Reuse bottles, molds as well as closure stock across all product line.

Here at Valiant Packaging We base the manufacturing process upon these standards in order in order to guarantee effectiveness, global compatibility as well as client satisfaction. It is the foundation of our operation and is a key reason world-wide brands depend on our product.

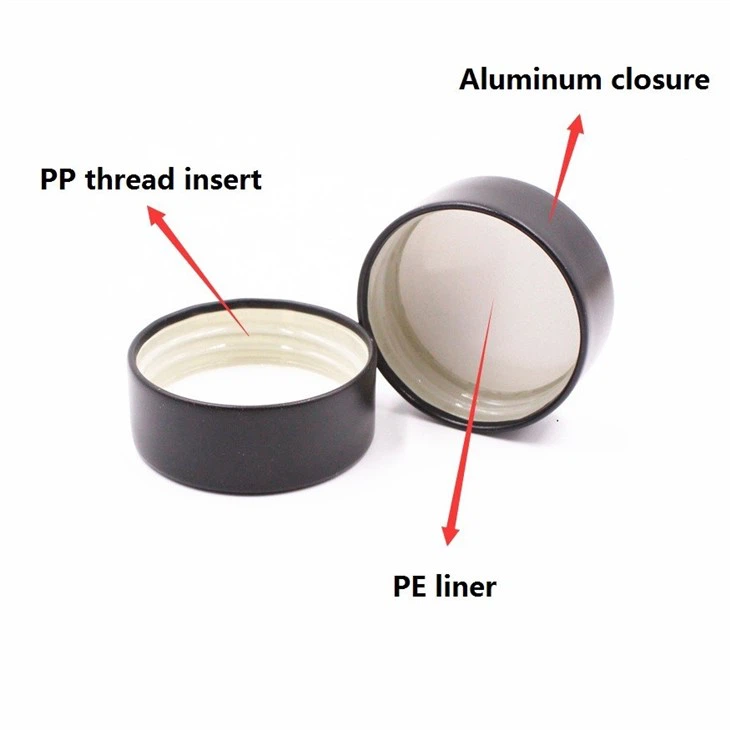

The Structure of GPI 33/400: Technical Specifications Explained

Let’s dive into the exact measurements and design of GPI 33/400 neck finish. GPI33/400 neck finishing. These measurements are vital to making sure that the bottle is properly fitted between the bottle’s closure and.

Here are the essential requirements:

- Outer Diameter of Neck: 33 mm

- Thread Style: 400 series This is the term used to describe a continuously running thread that has a single beginning

- Finish Height: Approximately 15-17 mm

- Thread Turns 1 Full Turn (360deg) to ensure optimal seal

It is the 400 Series thread is among the most popular and admired neck finishes for the marketplace because of its ease of use and flexibility. It permits easy capping and decapping even after many use, which is essential when it comes to reuseable or refillable packaging designs.

In addition, it’s compatible with tamper-evident closures such as sprayers, dropper caps and disc top caps as well as child-proof closures. This makes it ideal for items that require safety, precision as well as customer confidence.

Industries That Rely on GPI 33/400 Bottles

GPI 33/400 finish GPI 33/400 finish is popular in various industries. It provides unmatched flexibility and makes it a preferred option for a variety of formulations and liquids. Here are a handful of the industries that gain by using bottles that meet this kind of.

1. Cosmetics and Skincare

- Facial oils, serums, and beauty elixirs

- It is compatible to glass droppers and pumps

- Promots accuracy in application and integrity of the product

2. Pharmaceutical and Wellness Products

- Perfect to use for CBD oil, tinctures, syrups, as well as nutritional supplements

- Provides closings that are tamper-proof for markets that are regulated

- It offers Dosing control as well as a longer shelf life

3. Food and Beverage

- Bitters, infused liquors, aromatic concentrates

- It ensures the airtight sealing that preserves scent and taste

- It is used by top distilleries for bottling their exclusive blends

4. Aromatherapy and Essential Oils

- It is used for storing oil that is volatile with no degradation

- Glass is ineffective at interacting with reacting compounds

- Compatible with orifice reductioners and caps designed to be child-proof

Valiant Packaging, we’ve delivered personalized GPI 33/400 glass bottles to these various industries. We provide our customers with customized designs, solid finish, and flexible quantity.

Valiant Packaging‘s Precision in Manufacturing GPI 33/400 Bottles

When it comes to top-quality glass bottle production every millimeter counts– especially in the neck. Valiant Packaging utilizes precise mold making and automated production to make sure that every bottle is in compliance with GPI 33/400 specifications perfectly.

Our Manufacturing Strengths Include:

- Modern CNC Mold Design

Our molds are made with sub-millimeter accuracy to ensure that neck sizes are uniform across huge production runs. - Fully automated IS Equipment

The individual section (IS) forming machines enable continuous, rapid and top-quality bottle manufacturing that have minimal variation. - Quality Control in-house Our QA laboratory utilizes thread gauges as well as visual inspection systems as well as digital calipers, to check each batch to ensure uniformity and conformity.

- Flexible Customization ranging from embossing to engraving, to decorating and coloring, we provide custom-designed in-house decorations to fulfill the aesthetic requirements of our clients.

This high-quality manufacturing is backed by over two years of experience in the industry as well as a team with experienced engineers, as well as a commitment to sustainability in manufacturing.

Deconstructing the GPI 33/400: Why It Became the Industry Gold Standard

It is possible to wonder: if there are many possible neck finishes what is the reason why GPI 33/400 been so prevalent within the marketplace?

Simplicity Meets Functionality

The attractiveness in this GPI 33/400 standard is in the ease of use. Its one continuous thread which has a simple 33mm diameter allows it to be made easily as well as sealed in a reliable manner, which can be used again if required. It reduces any complexity in both production and the user’s viewpoints.

The thread’s standard size is suitable for items that need the use of a secure seal like essential oils and CBD Tinctures, in which leakage may compromise product effectiveness and the reputation of the company.

Machine Compatibility

From filling lines, to cap equipment From filling lines to capping equipment, for capping and filling equipment, GPI 33/400 standard is adaptable to existing automation systems. There is no need for any special modifications to accommodate the bottle style. Production facilities that are high-throughput this helps reduce downtime, increases yield as well as reduces costs..

We regularly work together with our customers to design GPI 33/400-compliant closures that are easily connected to automated lines for example:

- Systems for capping with torque control

- Induction sealing equipment

- Vacuum testing units

- Equipment for automatic labeling

Regulatory Compliance: Safety First in GPI 33/400 Packaging

A further reason behind the extensive usage for the widespread use of GPI 33/400 is conformity with hygiene and safety regulations. Around the world, regulators organizations like:

- FDA (U.S.)

- EMA (European Union)

- CFDA (China)

- TGA (Australia)

have strict requirements for packaging of cosmetic and consumable products. GPI 33/400 neck finish GPI33/400 neck finish enables the brand’s owners to use caps that are child-proof, tamper-evident seals as well as the shrink band to help them meet the requirements of these laws.

Valiant Packaging assists clients not just in the production of bottles, but also with:

- Label regulation audits

- Closure test and testing and

- Tests for compatibility with seal liner

- Food-safe and sterile coatings

Glass Bottle Trends Driving GPI 33/400 Adoption

The glass packaging market will be in excess of the $82 billion mark in 2030 The need for standard neck finishes is increasing in parallel.

These are the main developments that have fueled the growth of GPI 33/400 format. GPI 33/400 format:

1. Rise of Natural and Organic Products

People are increasingly gravitating towards natural cosmetics, natural wellness in the form of food products made from plants. The products typically contain natural oils and botanical tinctures or formulations that are chemical-free, and call for containers that are non-reactive–a feature for glass bottle.

Its GPI 33/400 finish is especially suited for these kinds of product because of its compatibility glass droppers, orifice reducers and sealed airtight sealing.

2. Customization and Brand Identity

In the space of premium goods packaging is usually the most important factor for consumers when buying. Companies want to be able to develop distinctive looks without sacrifice in the performance or compatibility.

Offering bottles that conform to those of GPI 33/400 standard yet differ in color, shape, or even design, Valiant Packaging helps clients achieve the right balance of design and functionality.

3. Sustainability and Circular Economy

In the quest for an circular economic system business are trying at ways to lessen consumption, reuse materials in a more efficient manner, and recycling effectively. Glass, which is 100% recyclable, already fulfills the requirements of these. GPI 33/400 is a format also promotes sustainable practices by being compatible refill programmes as well as closures that can be reused.

Material Considerations: Why Glass Remains the Superior Choice

Plastics are gaining an increase in popularity due to the costs and their weight, glass packaging is still the best product used for:

- Premium spirits

- Essential oils for aromatherapy

- Nutritional supplements

- Formulations for pharmaceutical use

Here’s why:

1. Chemical Inertness

Glass doesn’t interfere with the material within, which means the absence of loss of leaching, no flavor modification as well as the highest quality.

2. Shelf Life Extension

Glass products tend to last for longer. Essential oils, like are sensitive to light, while glass bottles that are coated with ultraviolet-resistant coats safeguard the formulation better than plastics.

3. Brand Perception

Glass conveys the luxury, trust as well as honesty–qualities important in all industries that branding is the key to revenue..

We are Valiant Packaging, we utilize soda lime glass that is high-purity and provide ultraviolet-blocking amber as well as cobalt blue choices which makes Valiant Packaging a top supplier to worldwide wellness and spirits companies.

The Valiant Packaging Advantage: A One-Stop Glass Bottle Partner

The decision to choose a bottle maker doesn’t only depend on who will create the glass, but also how they can create, design and decorate it, then package it and ship it on a scale.

This is what is it that makes Valiant Packaging the ideal choice for GPI glass bottles of 33/400 gallons:

1. In-House Mold Workshop

We create and manufacture every mold in-house. This allows to allow speedy prototypes, cost control and custom geometries that are adapted to your specific products.

2. Scalable Manufacturing

Our facilities can accommodate small-batch trials as well as massive-scale mass production that makes it easier for multinationals as well as startups to partner with us.

3. Dedicated R&D Team

We put our money into constant product development by studying the latest shapes, coatings and closure mechanisms for your packaging to ensure it is future-proofed.

4. Global Logistics Network

From shipping consolidation for sea freight from sea freight consolidation to the air-express We offer a variety of shipping choices. Our packaging is compliant with ISTA as well as the UN standards for transportation to ensure that the safety of your bottles no matter where you’re located.

5. End-to-End Branding Services

We are here to help in the following areas:

- Label alignment and graphic design

- Matching and sourcing of closures

- Shelf impact optimization

- Customization of packaging boxes

More Use Cases of GPI 33/400 Bottles in the Market

Let’s look at some of the practical application across various sectors using real-world examples to show the ways the GPI33/400 bottle can add value.

1. Luxury Beard Oil Brand

- Flint glass used using a black matte dropper

- GPI 33/400 closure offered excellent dispensing control

- Refill models helped cut down on packaging waste by 60percent

2. Boutique Bitters Company

- Glass bottle in Amber with a custom-designed label

- Tamper-evident cap made of aluminum ensured the product’s quality and integrity

- GPI 33/400 enables compatibility with bar equipment that is standard

3. Holistic Wellness Start-Up

- Bottle of cobalt blue used equipped with a cap for children.

- GPI 33/400 has guaranteed airtight storage for delicate botanicals

- Bottles are reused by customers in DIY applications. It helps build brand loyalties

Global Distribution: Where Valiant’s GPI 33/400 Bottles Are Used

GPI 33/400 bottles are shipped to over 150 countries. GPI 33/400 bottles are delivered to more than 150 nations that include:

- United States – for CBD spirit and oil markets

- Germany and France for top Aromatherapy products

- Japan and Korea used for skincare and cosmetics

- Australia and Canada – to purchase organic supplements

We know the regulations, design aesthetics as well as logistics challenges in each area which makes us an ideal business partner to help expand globally.

The Road Ahead: Innovation in Neck Finishes and Beyond

The industry of packaging continues develop The packaging industry continues to evolve, which is why GPI 33/400 is a key element of this evolution. Moving forward, Valiant Packaging is exploring:

- Bio-based glass substitutes

- Smart closures embedded with NFC tags

- Systems for modular refills utilizing GPI 33/400

- Supply chains that are zero-waste

We also test the latest techniques of decoration which include:

- Nano-etching

- 3D labellings with textured surfaces

- Glow-in-the-dark ceramic prints

- Multi-color screen printing that includes tactile feedback

This enhancement allows GPI33/400 bottles to be on the cutting edge of high-end environmentally sustainable and smart packaging options.