Executive Summary

The world’s spirits industry is experiencing a revolution in packaging. Although consumers for a long time have evaluated premium spirits based on the shape of its bottles, labels appearance, and closure a subtle but dramatic change has begun to take place. It is the advent of liquor bottles with shrink wraps. While once considered to be only functional and practical, these wraps are now playing crucial roles in branding differentiation, customer credibility, sustainability, and marketing appeal.

In the race to attract customers with their sophisticated tastes glass producers like Valiant Packaging have set the standard by combining technological innovation and the latest design techniques to make containers that are not just environmentally sustainable and safe, but also visually stunning.

The report examines the growth of shrink wraps within the spirit industry as well as the technological innovations that make their use, the benefits for sustainability and their impact on the marketplace which positions Valiant Packaging as a pioneer in this field.

Industry Context: Packaging in the Global Spirits Market

The market for spirits in the world is expected to reach 600 billion dollars over the next few years which is driven by the rise of premiumization distilleries that are craft, as well as emerging markets. In a time when consumers are increasingly seeking high-end services packaging is emerging as a major factor that differentiates brands.

Liquor bottles with shrink wraps are gaining popularity since they meet a variety of consumer needs simultaneously, including tamper evidence and brand communications attractiveness, aesthetics, and environmental sustainability. Shrink wraps enable distillers to make a single, highly-impact brand identity that is recognizable across the bars, shelves of retail as well as online markets.

Furthermore, regulations across a variety of regions are now requiring distinct evidence of genuineness and non-tampering. Shrink wraps can meet these requirements and offer designers an incredibly flexible and a wide-ranging canvas. In the case of emerging distilleries with craft it has been the most economical way to create a high-end appearance without spending a lot of money on labels or molds.

In the past, packaging for spirits was largely based on labeling with paper, wax seals, as well as metal capsules. However, as the use of the technology of film printing and digital printing developed, liquor bottles with shrink wraps were introduced as an innovative alternative, combining security and marketing. The industry analysts predict that, by 2030 more than 40% of the premium spirits worldwide will use at least one form of shrink-wrapping technology.

The Rise of Shrink Wraps in Liquor Packaging

Shrink wraps have gone from having only protecting purposes into an integral part of a marketing plan. A variety of reasons drive this increase:

Tamper Evidence and Safety

Today, consumers want confidence that the products they purchase are genuine and not altered. Alcohol bottles that have shrink wraps offer immediate proof of authenticity which reduces counterfeit risk as well as increasing confidence. When it comes to spirits with high value the feature could significantly affect purchase choices.

Premium Branding Opportunities

Contrary to conventional labels, these shrink wraps are able to cover the entire bottle and allow the full coverage of graphics such as metallic finishes, embossed texture. The one-off shrink wrap design could convey history, notes on flavor as well as the brand’s story with high-resolution colors, allowing small distilleries to stand out visually against global brand names.

Sustainability Advancements

Contemporary shrink films offer biodegradable, recyclable and compostable alternatives that are responding to growing demands from consumers and regulators for sustainable packaging.

Operational Efficiency

Automated shrink wrap lines can be used with large-scale production, and are flexible enough to allow small-scale batches. They lower the cost of labor reduce errors and improve the speed of bottling and make them attractive for small- and craft manufacturers.

The mix of design, functionality, and efficiency in operation creates shrink wraps as an ideal choice for distillers seeking to strike a balance between sustainability, cost and the effect on marketing.

Valiant Packaging: Innovation at the Forefront

A few glass makers have taken on this style of vintage liquor bottles with shrink wraps just like Valiant Packaging.

Meet the Dream Team

Valiant Packaging specializes in high-quality glass bottles for spirits producers. The range includes whiskey traditional decanters, contemporary Gin bottles, as well as custom limited edition styles. The company focuses on making bottles which represent the brand’s image with the goal of ensuring clarity, durability and a precise shrink wrap application.

President’s Note from CEO Dean Fan states: “Packaging isn’t just about the packaging of an item, but it’s an initial impression. It is the initial interaction between the brand’s owner and customer. Shrink wraps enhance that impression while ensuring safety as well as enhancing branding storytelling .”

Precision & Craftsmanship

Each bottle is manufactured using the latest manufacturing and finishing methods to ensure the perfect alignment of shrink wraps. High-end quality control system test for consistency, clarity, as well as visual fidelity, to keep uniform branding.

Sustainability Focus

Valiant Packaging sources eco-friendly shrink material and recycles the production waste and helps clients attain sustainability targets. Biodegradable and biodegradable materials are among the options. applications that are energy efficient.

Comprehensive Services

Beyond production of bottles Valiant Packaging provides custom design and printing, and installation that gives brands full control of their packaging and not having to rely on numerous suppliers.

The Manufacturing Process: How Shrink Wraps Transform Bottles

The production process used to make liquor bottles with shrink wraps is complex and involves mixing traditional glassmaking techniques with the latest materials technology. Valiant Packaging employs a multi-stage process:

- Design & Mold Engineering The bottle is designed with a design that is designed to reflect the character of the spirit and story of the brand. The molds are specifically designed for consistency in size, thickness and durability..

- glass production The finest raw materials are utilized to produce brilliance, clarity, as well as structural integrity. The quality control system ensures that there are no air bubbles, and a consistent weight.

- Shrink film Selection Materials: The selection will depend on the goals of the brand. There are a variety of options available, including PVC for low cost, PETG for clarity, PLA for biodegradability, as well as specific films for high-end aesthetics..

- Printing and Decoration Printing with high-resolution resolution provides stunning images, metallic accents and customized textures. Wraps may include QR codes, or even AR markers for increased engagement with the consumer.

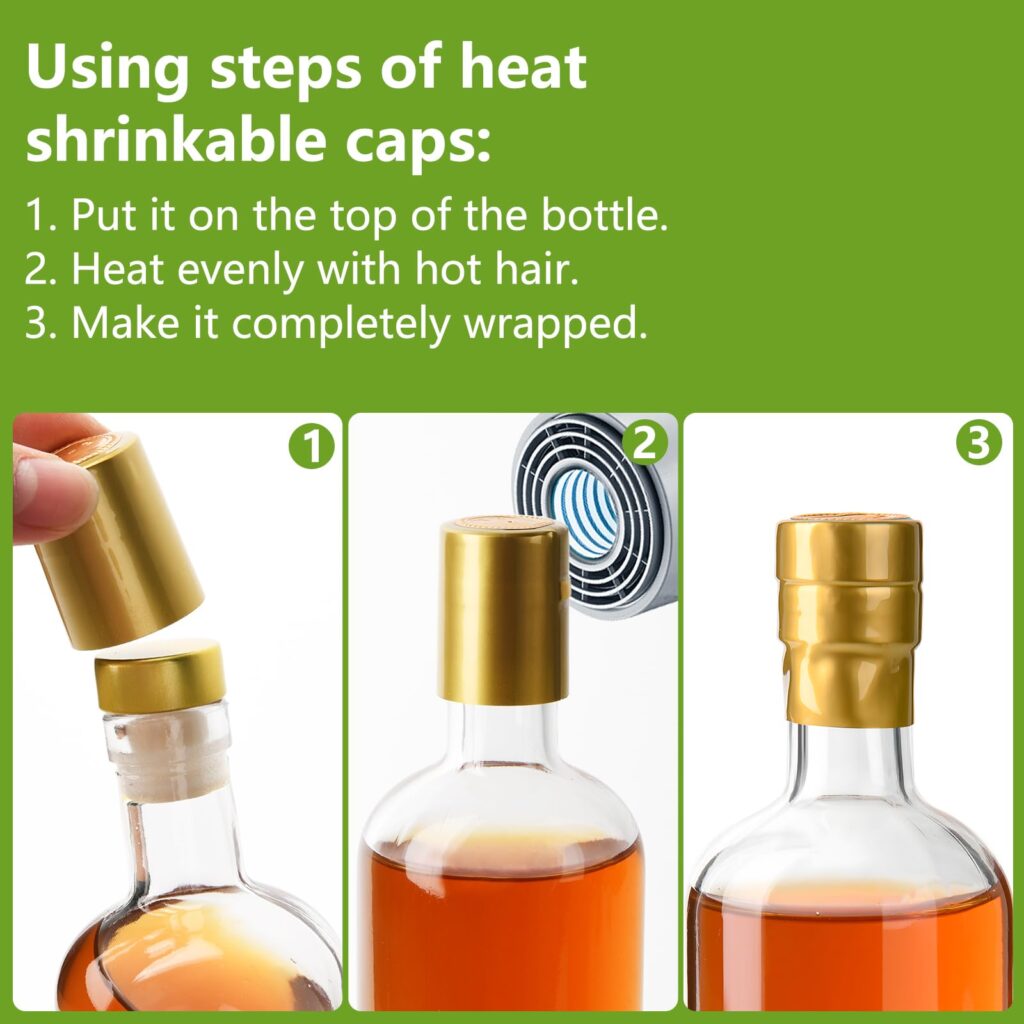

- Applications for Shrink Automated heating tunnels reduce the thickness of the film surrounding the bottle, resulting in an flawlessly conformed and free of wrinkles. Tunnel speed and temperature are carefully calibrated to ensure any distortion of the film or damage to the bottle.

- Quality Assurance: Every bottle goes through an inspection for wrapping align, adhesion and the quality of graphics assuring an unmatched quality appearance.

This is the reason liquor bottles with shrink wraps are now standard top packaging. They blend the aesthetics, function as well as durability all in one package.

Branding Benefits: Storytelling Through Packaging

Shrink wraps help brands effectively communicate both visually and emotionally with their customers:

- 360-Degree branding The whole bottle’s surface could be used to convey the history, flavors and brand story.

- Special Editions Campaigns that are seasonal or exclusive releases may use distinctive shrink-shaped patterns without changing molds.

- Interactive elements Embedding QR codes NFC chips or AR-related features within shrink wraps allows customers to gain access to digital media which includes tasting notes, stories about production or marketing campaigns.

Craft distilleries can benefit from this because it can be an efficient and cost-effective way of competing against multinational brands. In the case of premium spirits, shrink-wrappings increase the perception of worth by enhancing the product’s high-end positioning.

Sustainability & Material Innovation

In the last few years, environmental responsibility has been influencing how packaging is made:

- biodegradable films PLA and similar compostable film types reduce environmental impacts.

- Recycling Shrink Films: PETG and recycled PVC enable containers to be properly processed within the existing recycling channels.

- Energy-efficient Production Modern heat tunnels use less energy and release lesser greenhouse gas.

Valiant Packaging sets the standard in this field through a combination of the best aesthetics and sustainability. The clients can show environmentally responsible packaging with no compromise on style or quality.

Case Studies: Real-World Impact

London Craft Gin

A London distillery in London has incorporated liquor bottles with shrink wraps that feature botanical illustrations as well as metal accents. Its sales increased by 27% over the course of 6 months which demonstrates the effect of a premium style in influencing consumer choices.

Kentucky Bourbon Limited Edition

A Kentucky Bourbon company employed the gold-colored metallic shrink wrap that contained QR codes, which linked to the story of the brand. The online engagement grew by 33 percent while retailers also have reported faster turnover of their shelves.

Japanese Sake Export

A Japanese sake manufacturer has put in place environmentally friendly shrink wraps that feature holographic designs. Shelf visibility increased in international markets, increasing awareness in the competitive Asian urban areas.

Regional Adoption Trends

- North America: The power of creativity drives the adoption process; craft distilleries prefer vibrant, full-coverage wraps.

- Europe Sustainability and compliance with regulations encourage the use of biodegradable and recyclable film.

- Asia-Pacific The growing middle-class demands for top-quality packaging is fueling the need for innovation.

- Middle East & Africa Tamper-evident wraps offer the security and credibility for import spirits.

The analysts predict that, by the year 2035 over half of all premium spirits worldwide will make use of some kind of liquor bottles with shrink wraps.

Future Technologies in Shrink Wrap Packaging

The next phase of technological innovation is expected to transform shrink wraps in innovative solution for packaging:

- NFC Chips and AR Experiences Labels that are interactive allow users to gain access to information on tasting notes, history of the brand along with virtual tour.

- Temperature-Sensitive Inks: Indicate optimal serving temperatures.

- 3D wraps and texturing enhance the tactile experience, creating the Multi-sensory branding experience.

- Eco-Innovation Full compostable film as well as recycled post-consumer materials are now commonplace on premium marketplaces.

Valiant Packaging invests large amounts of R&D making sure that clients stay on top of the latest technological developments.

Economic & Supply Chain Perspectives

The effects of shrink wraps are on multiple elements of the supply chain

- Cost efficiency The automated application decreases labour and eliminates mistakes.

- inventory flexibility Brands are able to swiftly update shrink design for promotional events during the season or local preferences.

- Global Logistics: The use of protective wraps can reduce the damage caused by shipping as well as returns.

- Market premiumization A premium look permits brands to sell at higher prices and increase return on investment.

This is what makes liquor bottles with shrink wraps the ideal option for marketing and operational effectiveness.

Interviews with industry stakeholders

Dean Fan, CEO of Valiant Packaging: “Shrink wraps are much more than just protective films They are also an intermediary between the craft and consumer. The goal of Valiant Packaging is to provide distillers the ability to invent without compromising. “

Marketing Director London Gin Distillery: “The new shrink-wrap design has made our bottles immediately recognizable. Customers commented on how swiftly it caught their attention as well as our social media marketing campaigns gained thanks to the interactive features that we used. “

Sustainability consultant, European Spirits Council: “Innovations that are biodegradable, recyclable and compostable film are essential. The companies such as Valiant Packaging show it’s possible to combine sustainability and beautiful design. “

Conclusion & Market Outlook

The popularity of liquor bottles with shrink wraps is growing globally. The drivers include the demand for premiumization by consumers, a desire for authenticity sustainable, environmental sustainability, as well as interactive branding.

Valiant Packaging illustrates the way that technology and traditional can mix by combining the expertise of glass making, shrink wrap technology and environmentally sustainable products. With the world’s spirits market grows the shrink wraps industry is no anymore a mere accessory; they’re essential to the brand’s story along with product security as well as customer experience.

If you want your brand to be noticed on aisles, liquor bottles with shrink wraps provide the possibility of a attractive, practical as well as sustainable choice to ensure that each bottle represents the highest quality, authenticity as well as creativity.